What is a digital twin?

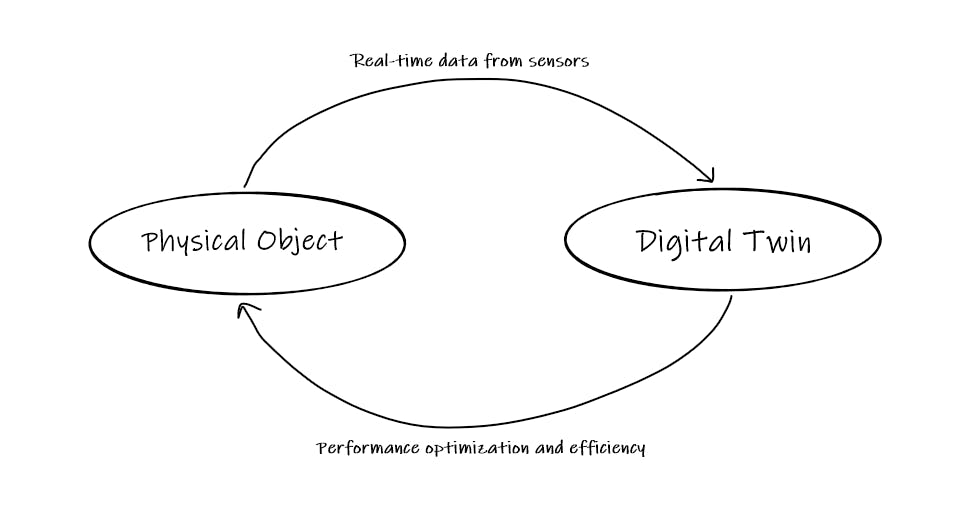

A digital twin is a digital replica of a physical object. The physical object may be a car, an engine, a turbine, etc… The digital twin, unlike a simulation, is completely virtual and has no limitations to its operations or performance. Being a replica of the physical object, initially, it gets the data from the physical object itself from the various sensors attached to the physical object. This data informs the engineers about every single part of the physical object and understands the working closely which helps them improve the functionality.

What can a digital twin do?

To better understand what digital twins can do, think of a smartwatch as a digital twin for the person who wears it. Now, the smartwatch initially gets the data from the person in the form of heart rate, calories burnt, sleep time, etc. With this data shown by the smartwatch, the person can understand how healthy he is or where he can improve.

Similarly, when the concept of a digital twin is used with bigger “things” like cars, jet engines, a building, or a tunnel, the digital twin can be used to monitor the physical object closely and simultaneously get real-time data from the physical thing.

The data received can be used to optimize the product further or find any inconsistency in the performance.

Further, with the data provided by the digital twin, the future of a product can be predicted and organizations can plan for the future of a product with much more confidence. Design and testing of a product will be drastically improved with the help of a digital twin as engineers will have a complete view of the product life cycle and they will be able to determine how a product might perform in the real world when it goes into production.

Machine learning and AI algorithms used with the digital twin will make the digital twin much more efficient in analyzing and predicting the future of a product. With metaverse in existence now, even the engineers could operate virtually from anywhere with the digital twin much more closely.

How can the space/satellite industry benefit from a digital twin?

Now that we have an understanding of how a digital twin works, let’s look at how it would take its place in the space and satellite industry where precision is everything. With the help of a digital twin, engineers can be monitoring the rocket much more closely and the real-time data from the sensors on the rocket will help in more clarity around what is happening. Even if something goes wrong, the problem can be found out quickly.

Research and testing is the most important aspect of the space industry and with digital twins, rigorous testing can be done. As the digital twins are completely virtual, the environment for the digital twins can be made the same as it would be in space. The data produced by the digital twin would be much more realistic and practical enough to predict the success rate of a rocket more precisely and know their limitations if there are any.

In the case of a satellite, just sending the satellite to orbit wouldn’t be enough, it should be able to link and communicate with other satellites efficiently. By implementing a digital twin, engineers can still monitor the satellite once it is in orbit. If the satellite runs into any problems, the engineers can look for any faults in the satellite using its digital twin and even troubleshoot the problem being thousands of kilometers away.

Rovers are another exciting part of the space industry. Sending them to other planets for exploration and finding evidence of life is important for human civilization. Currently, it would take months to just develop a rover, and testing the rover on various terrains costs millions. Adopting a digital twin for a rover can improve testing by virtually testing the digital twin in any terrain or environment flexibly. Engineers can gain more insights into how the rover performs on certain terrains and make changes to the materials used in the rover accordingly. Space organizations can save millions by adopting digital twins in the space industry and development periods would also decrease.

Conclusion

I think that now, we can see how impactful digital twins can be in engineering. In a world where almost everything is being digitized, a digital twin seems like an obvious and important change that should be adopted by business organizations. Products will undergo bigger and better changes in less time and innovations will come up more often to make the world a better place.